Wednesday, December 3, 2014

Tuesday, November 18, 2014

Monday, November 3, 2014

Assignment 8 - Catenaries

Base Curve was chosen then grasshopper script was written to pick up the midpoint by dividing point then call CullNth to pick up the midpoint

Orientation point is made to be on the curve perpendicular to the base curve.

Wax melted in Crock Pot

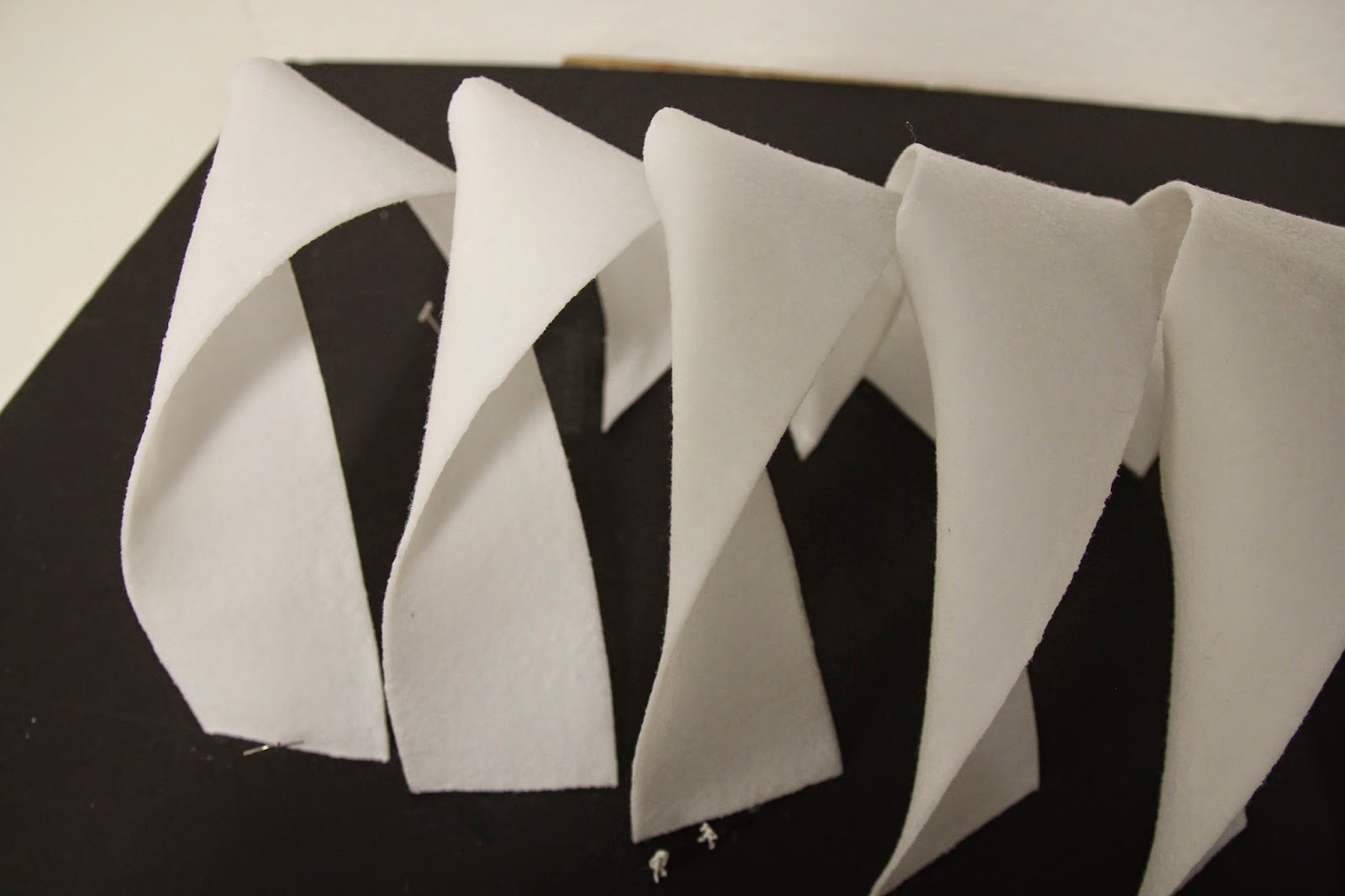

Pinning and Gluing

Friday, October 31, 2014

Reading 005_Lena Pfeiffer_Authoring Robotic Processes

This article Authoring Robotic Processes, by Gramazio and Kholer, discusses the shift from digitally designed architecture to digitally constructed architecture. It is no longer a relationship between "dematerialization and pure form" but of the construction of those forms from the digital realm into the 3D. With the introduction of digital fabrication, there are fewer limitations on the possibilities for construction. Through computational logic and material realization robots will be able to shift the parameters of design and fabrication. But it is important to use our design to inform the work of the robot and not the other way around, or else we will not be expanding our view of design. The robots must be approached as a tool for furthering design, not a limitation. One of the main advantages of the robot that gives it an advantage over many digital fabrication devices is its manual dexterity. This is the ability to be multi-functional because it is, in some form, "generic". This allows for endless tools to be used on the robot, such as the ones we used and constructed in class. This allows for options of building, placing, filming, painting, and so on, which in turn gives us very well rounded understanding of material and structure.

Scale is another factor that plays into the use of the robot. The robot arm can be placed on track and given a wider range of motion, but that can only take its motions so far. One project Granazio and Kholer discuss is their fly quadrocopters. The next step is to figure out how to apply this to full scale construction.

Scale is another factor that plays into the use of the robot. The robot arm can be placed on track and given a wider range of motion, but that can only take its motions so far. One project Granazio and Kholer discuss is their fly quadrocopters. The next step is to figure out how to apply this to full scale construction.

Thursday, October 30, 2014

Monica Reading Response 007: Retooling for Mass Markets

Tom

Verebes, an Associate Professor at the University of Hong Kong, speculates

about the use of robots in construction in his article, “Retooling for Mass

Markets in the 21st Century”. The title of his piece responds to a

quote by Thomas Kuhn, which states that retooling in manufacture is an extravagance

only necessary when a crisis demands it. Verebes argues that this crisis is

found today in China, where 10 million new urban inhabitants require housing

each year.

Because

of the urgent need for housing in China in what the author calls “The Asian

Century”, standardized building types are created for efficiency’s sake. The

approach to building threatens to turn Chinese cities into homogeneous environments

reminiscent of Modernist planning ideals. Robotic fabrication is a possible

solution for creating customized and unique cities, rather than systematic,

mass-produced ones.

Research

in robotic fabrication has been happening in elite architecture schools for

some time now, and these techniques have recently been adopted by some

entrepreneurs. However, although the technology is available and can be applied

at different scales, there are still many hurdles to overcome before robots are

used in the typical construction process. From a standpoint that considers only

time and money, it is impractical to change the current construction tools and

move robotic fabrication into the construction site. Instead of this, robots

should be used in conjunction with existing building technologies, not just to

save time and create efficient buildings, but also to create unique, beautiful,

and non-standardized cities for the world’s growing urban population.

Reading 007: Retooling for Mass Markets: Hillary Davlin's Response

"Retooling

for Mass Markets", written by Tom Verebes, poses a counterpoint for the

implementation of robotics in the 21st century, or as he terms it,

the “Asian-Century”. Today, robots have

slowly been integrated into architectural design, practice, discourse, teaching

and researching, but have hardly been considered in the physical building or a

contemporary city. Verebes argues that robotics poses great opportunity to aid

in the population demands across East Asian today. While robots may reduce both

time and money through the production of high-rise residential buildings, there

is a concern that robots may not be used to their full potential in order to

create variation rather than similar architectural typologies. Robots have been associated in the 20th

century with a monotonous, Fordism ideology, where repetitive products are

produced in a timely manner. Although

robots today have the same standardization ability, there is opportunity for

diversity through different tooling and robotic applications.

Customizing different robotic tools

has the ability to transform a city, allowing for a vast differentiation of

architectural high-rise typologies, while still doing so in an efficient

time. The question at this point becomes

not how robots can change urban skylines, but if they will be used to do

so. In the article, Verebe reiterates

Kittler’s stance on new technological media, stating that, “new media does not

make old media obsolete; they assign them other places in the system” (p. 129).

Robots, in this case, will most likely be combined with old building techniques

in order to address housing issues of the 21st century. The

responsibility thus relies on architects, developers, and city officials, if

the potential of robotic retooling will create a unique and successful city

skyline, or a dreary, monotonous urban fabric for the future population to live

within.

Tuesday, October 28, 2014

Monday, October 27, 2014

Thursday, October 23, 2014

Assignment 7.2 Jenga Wall

addition of script (1): adding "A+B" to move the location of all the points to the desired location on the table top.

addition of script (2): finding centroid of the top surface of the jenga block as the point to be picked up from the table top.

Addition of script (3): bypassing the script for generating the block. extract the points and resequence them to feed to the Gripper script.

The simulation of the Mitey.

We failed to finish the stacking since we ran out of robot time. Other issues was failing to assign the Tool so we decided to use the Pinhead tool instead (by copying all our codes except the tool into Pinhead's grasshopper file). Everything went quite smooth after that but since the tool is a little bit different we were spending most of the time calibrating it so we can use our jenga block script with the pinhead gripper tool.

Our blocks

Our work surface. This was so the pieces would lay flat on the slightly uneven table.

Placing a block. We had trouble changing the vertical height to account for the work surface.

Tuesday, October 21, 2014

Reading 006: Changing Building Sites - Hillary Davlin's Response

“Changing Building Sites”, written by Thomas Bock and Silke

Langenberg, explores the long history and potential of robotic automation on

the building site. Beginning n the 19th century, specific machines

have been necessary in aiding construction processes for new materials

(concrete, steel etc.) in the industrial revolution. For example, one of the

biggest architectural feats of the century, the Crystal Palace (built in 1851),

required new steam powered machines that could hold the large cast iron beams,

thus changing the physical building site. Progressing into the 20th

century, the destruction from WWI and WWII pushed the need for new construction

machinery as housing shortage reached an all-time high. Massed produced, prefabricated components

become the main mode of construction, changing machinery and building site even

further.

Prefabrication

in buildings and building systems advanced even greater during the 60s and 70s.

Standardized systems and mass production enabled time and cost savings, yet

again shifting the paradigm of building elements and site. During the 70s,

Japan hit a population and housing boom. Using similar mass production of building

systems, Japan adopted an automation system that replicated more of an assembly

line than actual automation. Robots slowly became introduced not only into

system production, but also into construction firms for the purposes of

demolition, surveying, excavation, paving, tunneling, welding, etc. on site. As

robots have transitioned from the factory to the construction site, it has been

argued that building sites are more successful if they are designed similar to

factories, where robots are fully integrated into the future production of a

home.

Monday, October 20, 2014

Assignment 7 - Jenga

grasshopper script 1 for the wall

We tried to isolate the grasshopper script that contains the gripper control from the last assignment. But then we failed to figure out the script for the sequence of picking up the bricks from bottom layer to top layer.

Brick Wall from different views

Gripper Tool

Subscribe to:

Comments (Atom)

%2B-%2BRhinoceros%2B(Educational)%2B(64-bit)%2B-%2B%5BPerspec.jpg)

.JPG)

.JPG)

.JPG)